|

|

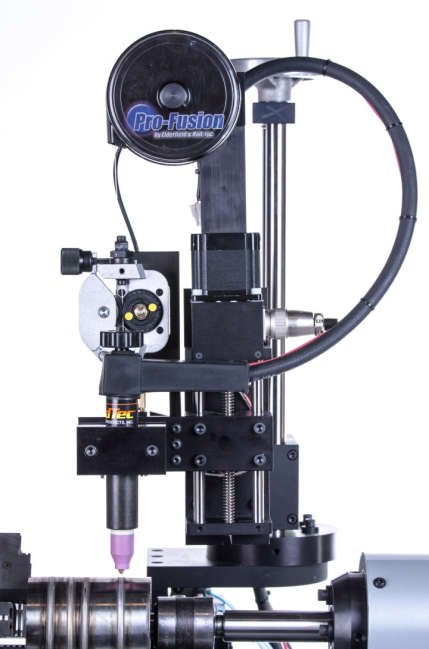

MODEL 3

|

Motorized slide is pictured mounted on a

lathe and WITHOUT the leadscrew guard.

Shown with optional wire feeder.

As shown on the attached pdf.

Use with either GTAW (TIG) or Plasma (PAW) Welding

processes to maintain a steady arc length by monitoring the

arc voltage and moving the torch up or down to compensate

for irregular surfaces. Benefits are:

- Improve weld penetration consistency

- Aid in having repeatable procedures

- Higher travel speeds

- Automatic & repeatable arc gap setting

- Easy set up

- Easy programming via Touch Screen Panel

The PF-AVC is designed for precision welding applications:

- Max welding current 300 Amps

- Available in 50 amp and 100 amp versions in order to use the broadest scale of sensitivity at lower amperages

- Max. Arc Voltage 70V

- Heavy duty, U.S. made stepper motor

- 2.75" torch travel

- Universal V-block torch mount

- Torch diameters: ¾" - 1 5/8" (19 - 42 mm)

- 40 lb. Weight Capacity (18 kg)

- ± 0.1V voltage accuracy

- ± 0.002" Arc Gap Setting Accuracy

- Deadband 1.5V

- 24 ipm Max. Drive Speed (600 mm/min)

- 0 - ¼" Touch retract range (0 - 6 mm)

- 0 - 2.75" Stop Retract (0 - 89 mm

- Jog Up/Down Control

- AVC Start Delay 0 - 20.0 Seconds

- AVC Retract Delay

- Arc Time Out Alarm 0 - 50 Seconds

- 2 Independent Output Relays to Control a power supply and a motion device or wire feeder

- Response Delay Timer 0 - 10.0 Seconds

- Voltage Pre-set Operator Override

- 115 / 230 Volt Input

- Optional Cold Wire Feeder Control

- Optional Remote Pendant

- Optional HMI control can load settings for lathe, AVC, wire feeder and power supply, up to 100 jobs directly via Modbus commands

- MADE IN AMERICA

About Pro-Fusion

Copyright © 1999-2019 Pro-Fusion by Elderfield & Hall.

10901 McBride Lane

Knoxville TN 37932

Tel: 865.671.7682

email: sales@pro-fusiononline.com

Privacy Policy, Shipping, Terms & Conditions