|

|

|

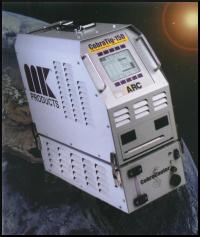

MK CobraTig® 150

Digital GTAW Orbital Tube Welder

|

| CobraTig® 150 Shown with Optional CobraCooler |

Weld Circles Around the Competition!

The portable, lightweight CobraTig® 150 with SmartArc® provides the automatic control you need to deliver repeatability, verification and traceability in high integrity orbital welding.

SmartArc® software develops a near ideal weld procedure through the use of our Automatic Procedure Generator. Just enter the tube OD and wall thickness - the rest is automatic.

The rugged construction of the portable CobraTig® 150 is the perfect package for your construction environments ... and the CobraTig® 150 weighs only 42 pounds (19.1 kg)!

The optional CobraCooler water supply fits tightly under the power supply providing water cooling for any MK weldhead. All CobraTig® 150 systems are shipped in a sealed rugged case with wheels.

Features At A Glance

- User Friendly LCD Program Screens

- Weighs just 42 Pounds (19.1 kg)

- 150 Amps @ 100% Duty Cycle

- Auto Procedure Generation

- Complete Data Monitoring

- SmartArc® Digital Controller

- High Speed Thermal Printer

- Optional Integrated CobraCooler

Model 254-150 CobraTig 150

Digital Welding Power Source Features

- 150 amps pulsed or constant current stable down to 1 amp.

- High Voltage Pulse automatic arc starting to 25 amps.

- Orbital and manual weld modes of operation.

- (APG) Automatic Procedure Generation, simplifies orbital weld procedure development by creating a near ideal procedure from basic input data such as tube OD and wall thickness.

- Automatic Tacking feature provides up to 7 opposing tack locations around the weld joint circumference.

- Automatic orbital weldhead speed calibration.

- (8) weld levels for smooth current and motor sloping around the circumference plus upslope and final slope.

- Level by level scaling software remembers, and recalculates upon demand, all modifications performed by the operator during the orbital weld resulting in a "new" weld procedure that can be saved for future use if desired.

- LCD display provides automatic light sensor for day or night viewing.

- Integrated high-speed thermal printer provides real-time weld data monitoring and post weld reporting of orbital weld procedure text and waveform graphs.

- Soft-key front panel keypad for user interface.

- Store and modify up to 25 orbital weld procedures.

- Metric and English units for orbital weld data input.

- 3 range manual weld modes, 0-50, 0-100 and 0-150 amp ranges, constant or pulsed.

Data Monitoring and Performance Logging

- Data monitoring of faults detected during the weld sequence, including gas, current, voltage and motor.

- Performance logging of weld parameter text and graphic wave forms, such as current, voltage and motor. For monitoring and logging output deviations from demand values.

Computer Control System

- Micro-controller

architecture Proprietary multi-tasking operating software - Computer memory

Dual Micro-Controller design with non-erasable loader program and FLASH user up-datable memory for software storage. Non-volatile SRAM for user programs (saved on power off). - Infrared Communication port

Transfers weld procedures between CobraTig® 150's. - Software Updates

Through RS 232 cable from computer/laptop. Off-Line Program Generation with Windows® NT/95/98 Software Program. Also Convert ACL Custom Procedures. - Program Storage

25 weld procedures in machine, unlimited on floppy disk.

Technical Specifications

| Line Power: | 100VAC (+/-10%), 60 Hz single phase

120VAC (+/-10%), 60 Hz single-phase 208/240 (+/-10%), single or 3 phase, 50/60 Hz, 30 amps. |

| Output Current: | 150 amp, (+/- 1%), constant or pulsed. |

| Pulse Rate: | 0.01 to 2.55 seconds per pulse. |

| Arc Voltage: | 65VDC open circuit, up to 26VDC while welding. |

| Loop Response: | 1.5 KHz. |

| Current Reg. Frequency: | 30 KHz. |

| Motor Control: | 24V, 2 amp maximum DC tachometer feedback. |

| Weight | 42 lbs /19.1 kg |

| Height | 14 in /35.6 cm |

| Width | 8.5 in /21.6 cm |

| Length | 19 in /48.3 cm |

Options

- 250-150 CobraCooler

- 005-0610 Accessory kit

- 005-0652 AmpTrack Torch Control kit

WeldHeads Supported

- Model 5000 MK Mr. Micro Weldhead.

- Models 5001-5003, MK Copperheads.

- Models 6004, MK Cartridge Weldhead.

- Arc Machines Weldheads

- Astro Arc Weldheads

About Pro-Fusion

Copyright © 2010 Pro-Fusion by Elderfield & Hall.

222 N. Maplewood Ave

Chicago, IL 60612 USA

Tel (800) 747-9353

Fax (312) 829-6733

email: sales@pro-fusiononline.com

Privacy Policy, Shipping, Terms & Conditions